Core connected to the heart and happy to share

Home>Products>Outdoor Optical Cables>Non-Metallic Loose Tube Stranded, Reinforced Armored, Flame Retardant Optical Cable

Home>Products>Outdoor Optical Cables>Non-Metallic Loose Tube Stranded, Reinforced Armored, Flame Retardant Optical Cable

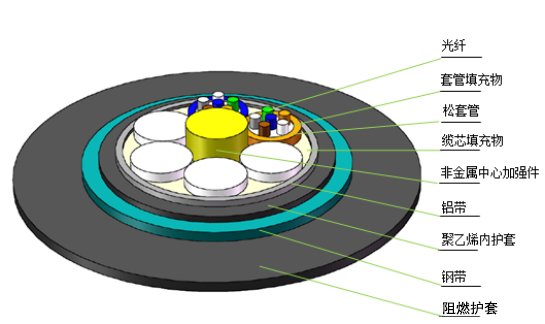

The GYFTZA53 optical cable structure involves inserting 250μm optical fibers into loose tubes made of high-modulus material, with the tubes filled with waterproof compound. The cable core centers on a non-metallic strength member, which for certain fiber counts is additionally coated with an extruded layer of polyethylene (PE). The loose tubes (and filler rods) are stranded around the central strength member to form a compact circular core, with interstices filled with water-blocking material. A longitudinally applied plastic-coated aluminum tape (APL) is sheathed before extruding an inner polyethylene jacket, followed by a longitudinally applied double-sided plastic-coated steel tape (PSP) and finally extruded with a flame-retardant outer jacket to complete the cable.

Purchase link

- Product Features

- Optical Cable Structure Diagram

- Product Standards

1. Excellent mechanical and temperature characteristics.

2. The loose tube material itself exhibits high hydrolysis resistance and superior strength.

3. Filled with specialized thixotropic gel, providing critical protection to the fibers.

4. Good crush resistance and flexibility.

5. The flame-retardant jacket offers excellent fire resistance properties.

6. The following measures ensure the cable’s water resistance:

?· Single non-metallic central strength member

?· Loose tubes filled with specialized waterproof compound

?· Complete cable core filling

?· Plastic-coated aluminum tape (APL) moisture barrier

?· Double-sided plastic-coated steel tape (PSP) enhances moisture penetration resistance

?· Effective water-blocking materials prevent longitudinal water seepage

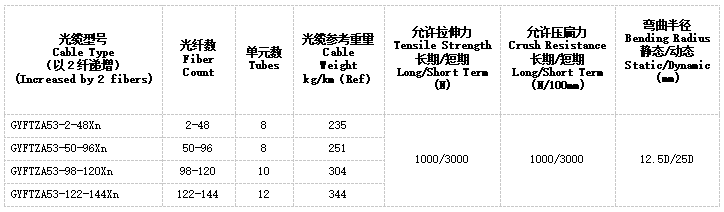

Structural Parameters

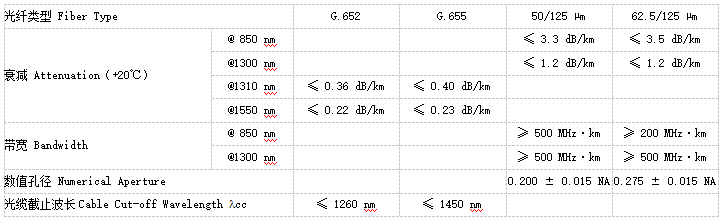

Optical Characteristics

Application: Duct, Aerial, Direct Burial

Storage and Operating Temperature: -40℃ to +70℃

The GYFTZA53 optical cable from LeFei Optoelectronic Co., Ltd. complies with YD/T 901 and IEC 60794-1 standards.